The colorants in plastic moulding are made up of various organic and inorganic pigments. Depending on the end colour, these will be blended together into the carrier resin. This carrier resin is generally from the same family as the closure resin it will be moulded in to form the finished closure. A HDPE closure will have a PE carrier, while a PP closure will tend to use a PP carrier.

There is often a need for a mix of both organic and inorganic pigments to get both the desired colour and the depth of colour. These multiple pigments react differently in the mould as the crystallisation (cooling) of the part occurs before ejection. The crystallisation process continues well after the part has left the mould and continues to cool (often up to 5 minutes).

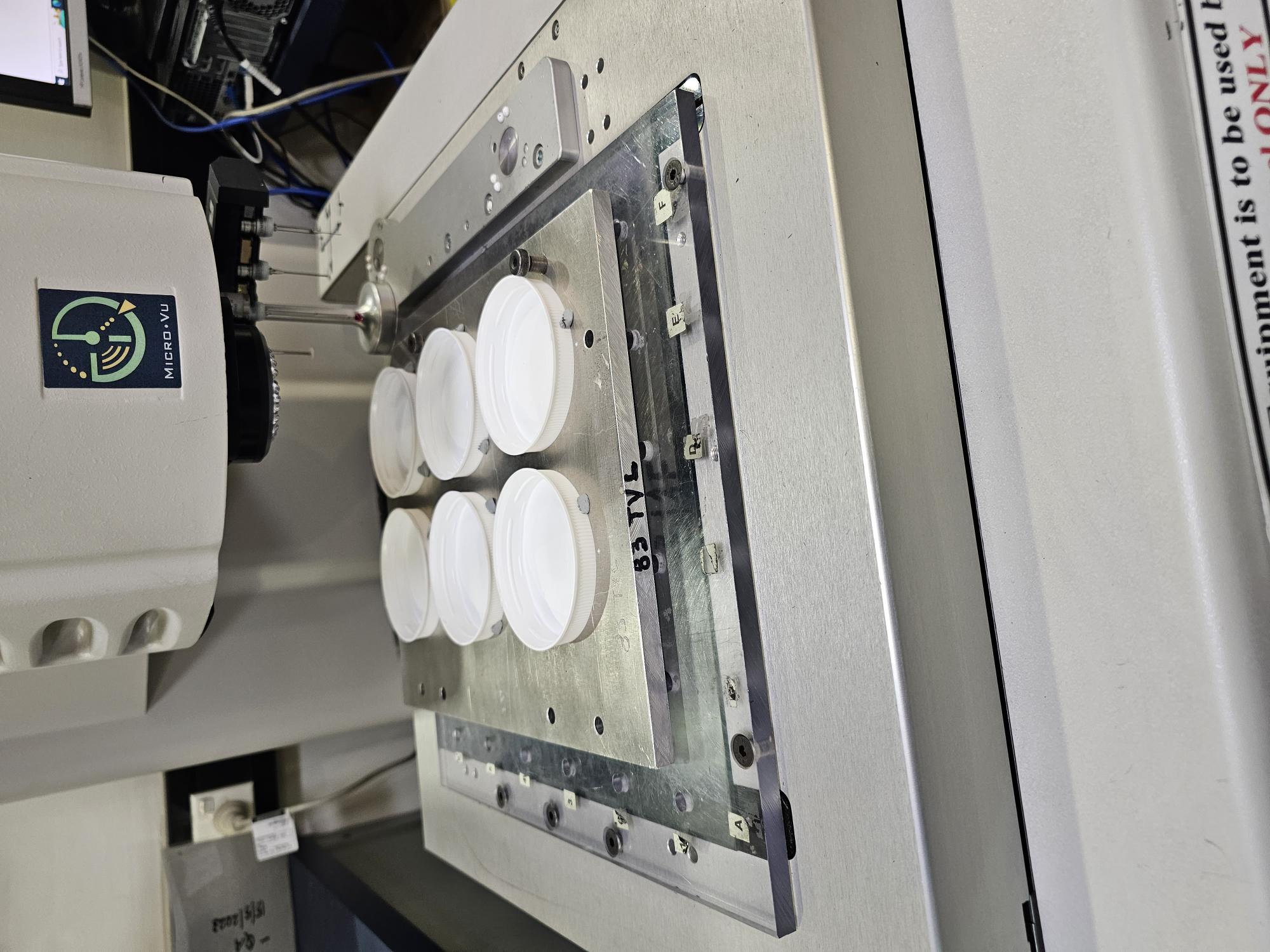

Part of the first test of a new colour master batch will be measuring any shrinkage or warping of the cold closure, checking for size variation against the baseline clear closure, then providing this information back to the master batch manufacturer so they can adjust the pigments for a better result.

We know that green, blue, and particularly purple colours are the most difficult to get the combination of colour, the depth of colour (so no transparency) and the sizing when cooled.